dump cycle autoclaves liquid|autoclave liquid vs gravity : company Autoclave Incident 1 • 2001, several bottles inside autoclave exploded because they were tightly capped • In response, 3 workers investigated the explosion, and opened the autoclave door. • While standing in front of the open door, additional bottles exploded and . Used to detect the ability of bacteria to hydrolyze the lipid, Tween 80. Adjust pH to 7.4. Autoclave and add Tween 80 (autoclaved) at 10 ml/liter rate. Pour into Petri plates. Spot or streak .

{plog:ftitle_list}

The following 200 pages are in this category, out of 280 total.

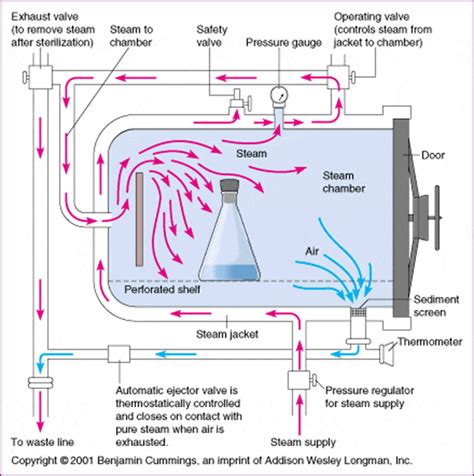

Biological Waste (Gravity Cycle) Liquids (Liquid Cycle) Dry Items (Gravity Cycle) Glassware (Gravity Cycle) Preparation Open the bag >2", Place in tray, Place indicator if needed Loosen caps or use a vented closure, Fill containers no more than 75% capacity Fabrics Wrap; Instruments: Clean, dry, lay in pan Dirty: Place in middle of the pan;Autoclave Incident 1 • 2001, several bottles inside autoclave exploded because they were tightly capped • In response, 3 workers investigated the explosion, and opened the autoclave door. • While standing in front of the open door, additional bottles exploded and .The material of the container can also factor into autoclave cycle specifications needed, as they will reach temperatures at different rates. For instance, metal containers conduct heat significantly faster than glass. . Benchtop autoclaves .The exhaust phase of the cycle must therefore release pressure slowly to allow the liquid to cool off as the pressure decreases. More efficient sterilising You can use load sensed timing whereby a flexible sensor probe is fitted and submerged directly into the media or reference bottle so that the cycle is controlled directly by the temperature .

The material of the container can also factor into autoclave cycle specifications needed, as they will reach temperatures at different rates. For instance, metal containers conduct heat significantly faster than glass. . Benchtop autoclaves are the perfect solution for media prep, liquid, and waste loads. They are an ideal fit for small or . Cycle Types: Pre-vacuum, liquid, liquid with optional air cooling, gravity, bio-waste, F 0, load probe, isothermal, and maintenance cycles Chamber Dimensions: 20” x 20” x 38” Chamber Volume: 249L

Fill liquid containers only ½ full and loosen caps or use vented closures. During Autoclaving. DO NOT autoclave liquid and dry material together. Segregate autoclave loads (infectious waste, liquid, or labware). DO NOT LEAVE AUTOCLAVED MATERIAL IN AUTOCLAVE OVERNIGHT!!! Use appropriate cycle times for autoclaving. See the autoclaves .

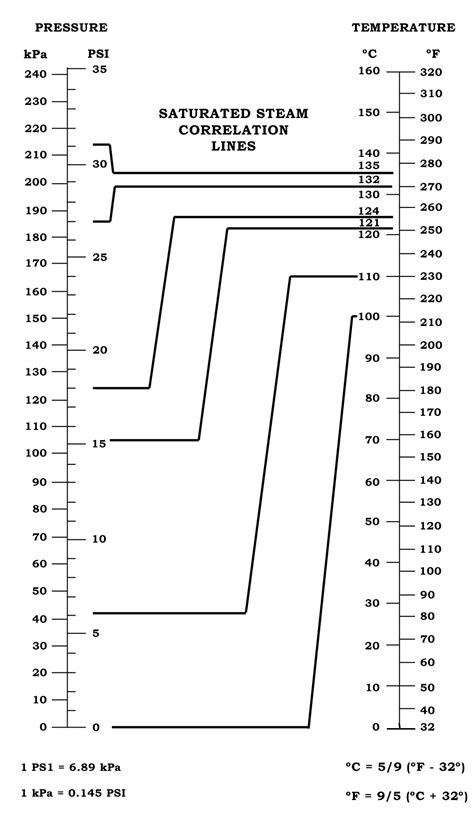

Never autoclave a sealed container of liquids as this may result in an explosion of superheated liquid during the cycle or when the container is opened. . as glassware (for example, media bottles, beakers, and flasks), spatulas, magnetic stirrers, etc., and biohazardous waste (if Pre-Vac cycle is unavailable). Liquid: Gravity cycle with .Generally, autoclave waste cycles for solid waste are of the pre-vacuum pulse/post-vacuum type as illustrated in the graph above. This insures that steam reaches all parts of the load. Autoclave cycles for typical mixed solid biohazardous waste should achieve a temperature of5. Setup and ensure the parameters for the waste cycle are: temperature = 121oC, pressure =15 psi, time = 60 minutes Place tray containing the bag in the center of the autoclave and run a steam cycle of the parameters used for waste decontamination. For soil and agar plate waste use a liquid cycle. 6.To be effective, the autoclave must reach and maintain a temperature of 121° C for at least 30 minutes by using saturated steam under at least 15 psi of pressure. Increased cycle time may be necessary depending upon the make-up and volume of the load. . •Liquid biological waste : Solids or Dry cycle (Fast Exhaust) Glassware: empty and .

A liquid cycle is a sterilization cycle in which steam is exhausted slowly at the end of the cycle to allow the liquids to cool without boiling over. 2. A kill cycle is a liquid cycle with a duration of 180 minutes to sterilize bio-hazardous waste. 3. A gravity cycle is a sterilization cycle in which steam is rapidly exhausted at the end of the . In many research and diagnostic facilities, liters of biologically contaminated liquid waste are produced on a daily basis and need to be safely disposed of. The gold standard is steam sterilization, namely, in most cases autoclaving for 20 minutes at 121°C. Here we demonstrate the importance of the following parameters when autoclaving liquid waste .A 60 minute autoclave cycle (excluding exhaust time) is recommended to allow enough time for the center of the load to come up to temperature and have sufficient steam penetration. This . • To autoclave liquid waste, place liquid in beaker or flask, not in autoclave bag.This protocol also describes the procedure for verifying that the autoclave KILL cycle used to sterilize biohazardous waste is operating within expected parameters. 2.0 DEFINITIONS: 2.1 NIST = National Institute of Standards and Technology 2.2 Completed Liquid Cycle (for autoclave #s 1 and 2) = a complete autoclave liquid cycle includes the .

• Autoclave cycle parameters are determined by lab- specific risk assessment • Common cycle types programmed for autoclaves • Gravity displacement • Vacuum . • Used for media, water, liquid biological waste, etc. Environmental Health and Safety. Autoclaving Liquids • Liquids should only be autoclaved in autoclaveable glass

Autoclave Cycles CYCLE TYPE: RECOMMENDED FOR: NOT . . 40 min. Nonflammable liquids • Aqueous solutions • Liquid biowaste . D. RY ITEMS. that . don’t require a slow exhaust : 121º C . Sterilize time = 30 to 60 min. Cool Time = Approx. Run Time = 70 to 100 min. . Biohazard waste decontamination (in autoclave bags; can be wet + dry . Every modern research lab autoclave has a “liquid cycle”—a cycle just for processing liquids, growth media, and so on. Nonetheless, more often than not, if you fill a bunch of 1L bottles up to 900mL and process them on the “liquid cycle” they’re going to come out like this: The glass isn’t cracked; where did the liquid go? Some evaporated, but most of it boiled .%PDF-1.7 %âãÏÓ 4276 0 obj > endobj 4288 0 obj >/Encrypt 4277 0 R/Filter/FlateDecode/ID[1564B57341670E45ABF57AA58477559A>]/Index[4276 29]/Info 4275 0 R/Length 79 . sterilizing liquids, it is imperative that the liquid cycle is selected to prevent boil over during the exhaust portion of the cycle. Again, liquids should be allowed to cool sufficiently before removal as disturbing the liquids can result in a boil over. 11. Once the cycle has started, did you verify that the autoclave was functioning properly?

Medical Waste Autoclaves 5 3 6 4 Waste Treatment Sterilization The waste is sterilized by autoclaving using steam at high pressure and temperature (134ºC). This ensures that the biologically harmful elements of the waste are destroyed. Compacting Compacting is an optional stage that significantly reduces the volume of the sterilized waste into aThe 5596 medical waste autoclave provides many advantages for on-site medical waste treatment and off-site disposal of medical waste. . urine and other liquid medical waste a flexible PT100 placed in liquid waste load ensures sterilization at an effective sterilization temperature. . Built-in fast cooling reduces cycle processing times .Autoclave trash = Cycle 6; Autoclave liquid trash = Cycle 3. As a general rule of them, dry biohazardous trash should be autoclaved for a minimum of 2 hours at 121 degrees celsius, and liquid biohazardous trash should be autoclaved for a minimum of 1 hour. . If there is a lot of boil over, place autoclaved bag into another biohazard bag, dump .The liquids cycle in an autoclave operates on a modified gravity cycle, tailored to control the cooling phase and extend the duration of the heating phase. Although the sterilization temperature employed is 121°C, the duration depends significantly on the volume of the liquids and the size of the containers. . This ensures that if a liquid .

30 program cycles are available with each autoclave. Up to 8 cycle programs are factory set according to optional features. The remaining cycles are fully customizable by the user. . Solid and glassware loads at 134°C or 121°C for delicate loads (plastics) Liquid loads and waste liquids at 121°C; Standard Cycles added with Optional .30 program cycles are available with each autoclave. Up to 8 cycle programs are factory set according to optional features. The remaining cycles are fully customizable by the user. . Solid and glassware loads at 134°C or 121°C for delicate loads (plastics) Liquid loads and waste liquids at 121°C; Standard Cycles added with Optional .

7180 chemistry analyzer

what temp is an autoclave

sterilization time temperature chart

$132.00

dump cycle autoclaves liquid|autoclave liquid vs gravity